Reduce effort

Forward-looking labor management and scheduling of all resources will lead to a holistic optimum, considering performance and costs. Thus, system and personnel efforts will be minimized.

Increase Performance

Bottlenecks and overcapacities are detected by the redPILOT algorithm. As a result, action alternatives are proposed, decisions can be made based on real date and the performance of the overall system increases.

Optimize operations

Machine-based learning automatically improves the system itself, which steadily enhances your operations in a systematic way and detects hidden potential.

It is our aim to achieve the ecological, social and economic optimum for your logistics systems, by focussing on optimized planning of available resources and sustainable improvement.

We provide the world’s only

holistic solution to run your logistics operation at optimum level.

Operational Excellence in Action

Achieving operational excellence means sustainable improvement. This will not only help you to increase key performance metrics but also meet customer expectations better.

For further insights into the redPILOT solution and how it supports you to optimize warehouse operations, request our videos and case studies.

Master Intralogistics Challenges

Logistics operations need to excel in a highly competitive environment. No matter if large, small, complex, or simple: they need to work under constantly changing conditions. Your operation will undoubtedly face similar challenges. Which of the following questions concern you as well?

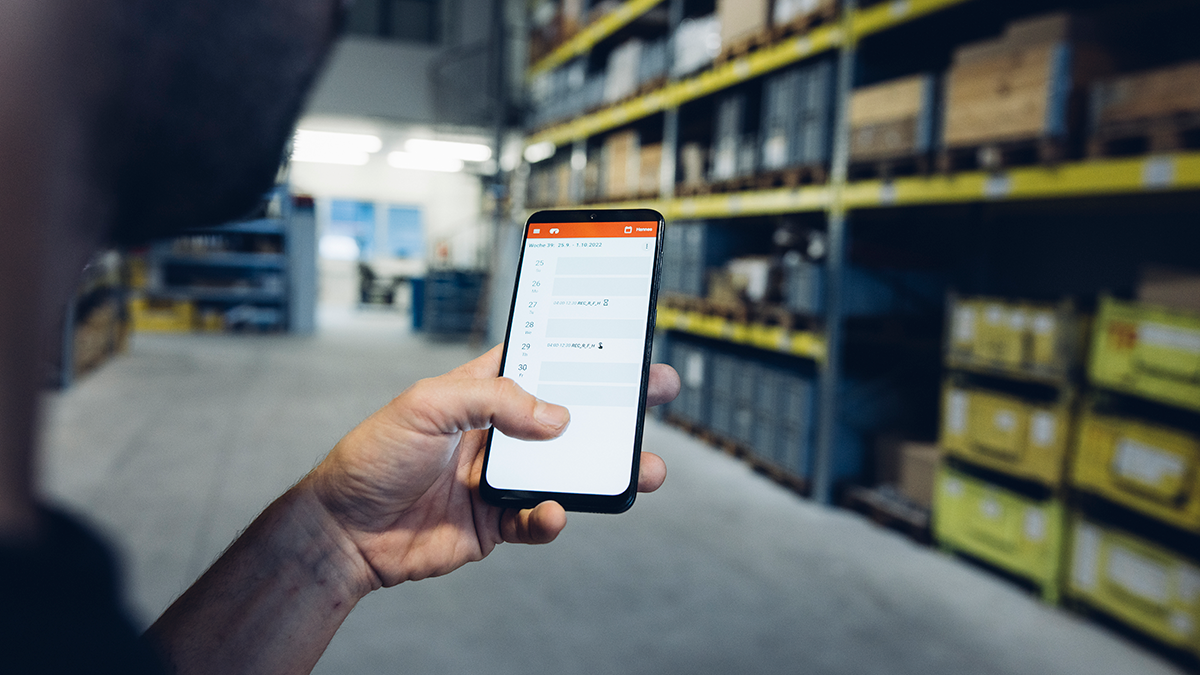

Logistics operations are under constant pressure to react to the environment they are operating in. redPILOT Operational Excellence Solution supports management on various levels by providing data-based decision support and action alternatives. Traditionally siloed data sources are unified so that managers can get a holistic picture of their facility. Data from ERP, OMS, WMS, WES, WCS, LMS, and any other relevant subsystem are brought together in order to provide a clear picture of demands, available resources, and their capabilities. Our innovative solution is based on the core principles of operational excellence, designed to optimize your warehouse performance and meet customer expectations.

We are your partner for optimizing

logistics operations.

Operational Excellence News

Our Happy Clients

Our customers work in different industries worldwide.

Food retail

Cosmetics

Electronics

Online retail

Pharma

Logistics